Why Poligon?

It Starts With an Idea

All projects, no matter the size, first start with an idea to create something. This idea is only a thought until someone decides to take action and apply it to paper where it becomes a layout or blueprint of the concept. This layout then turns into a design that is very specific and unique to this application or location. Once the design is determined, the manufacturing of the concept begins. This phase of development is the most crucial to providing the correct end result desired for the project. The manufacturing of the material components is what ultimately takes the original idea and manifests it into a physical project. This is the area of expertise that Poligon excels in. Custom creations are their specialty!

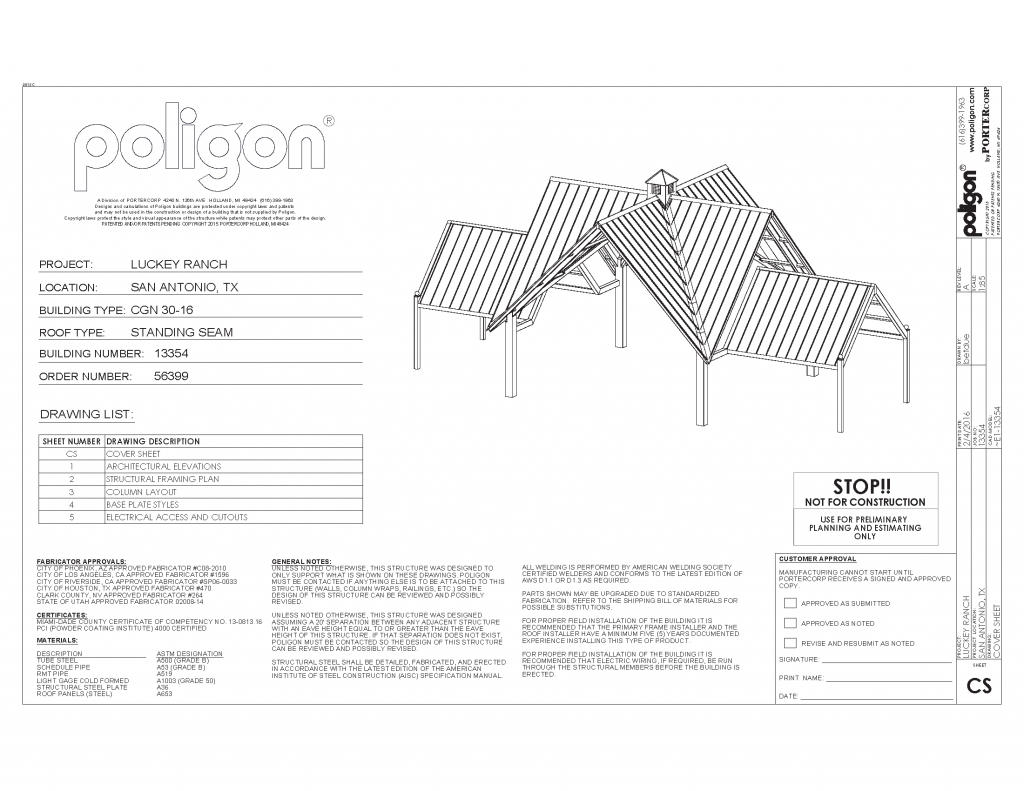

Design

Every Poligon is designed and engineered specifically for its site. Each project starts with the initial contact of the customer and this spurs the discussion of objectives, timelines, budgets, and; most important, customer ideas. Every Poligon begins with the initial concept of the customer’s wants and the end location’s needs, then is refined to perform the task needed. From there the engineers work to create a design that will complement the surroundings of the location and draw attention to the local environment. Poligon can work from existing drawings or can create original designs if needed which can save time and cost on the part of the customer. The Poligon engineer team is qualified to provide stamped, sealed drawings; complete with foundation design, for permitting purposes which can also save the customer time and money. The production of the custom shelter will not commence until everyone affiliated with the project is in agreement that the design is what is needed for the location. Poligon ensures customer satisfaction prior to the construction of a shelter.

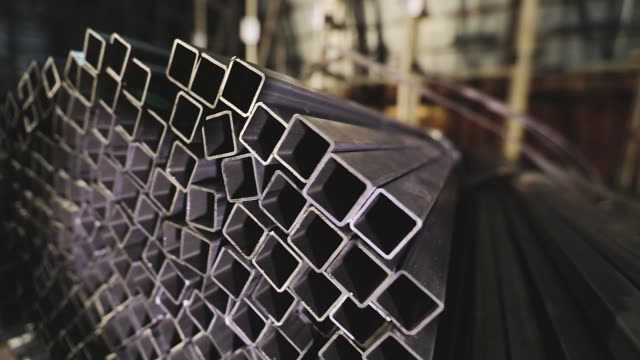

Materials

The AISC (American Institute of Steel Construction) sets the standard for the structural steel industry and Poligon is AISC certified, which should be a minimum requirement for any metal structure fabricator. Since Poligon is AISC certified, all steel used in the fabrication and production of Poligon’s metal frame structures meets the AISC requirements. The metal roofing components feature 24-gauge multi-rib, standing seam, or mega rib panels with a Kynar 500 finish. Poligon also offers roof substrate options which include stained 2″ x 6″ Hem-Fir tongue and groove decking or 4-1/2″ thick structural insulated panels with a 7/16″ OSB top surface which incorporates a 3-5/8″ thick EPS foam core and a 5/8″ thick reverse board and batten Fir plywood laminate. In adding the finishing touch, Poligon offers three finish options; standard Poli-5000 finish, hot-dip galvanized finish or duplex coating finish which is a combination of the first two. More options and specifications are available as applicable to the customer’s specific project. Each Poligon structure is unique and so are the materials and specifications needed to complete the design. If you have questions about Poligon’s specifications, please ask them here.

Certifications

As mentioned above, Poligon is an AISC certified building fabricator and they are the only one of several competitor companies that hold this certification. Poligon has been approved by several cities and counties across America as a steel fabricator as well. Another distinguished certification of Poligon is its PCI 4000 certification. This honor requires an extensive audit program that evaluates business practices, process elements, equipment, capabilities, employee competencies, and quality control capabilities of a coater to ensure they are capable of producing a high-quality powder-coated product with a high degree of customer satisfaction. Poligon takes pride in its current certifications and is always striving to improve their current status.

LEED Points

Poligon can assist your project with LEED certification. The following categories may qualify for LEED points with a Poligon structure being used on your project.

- Sustainable Sites – Credit 4.2 – Alternative Transportation, Bicycle Storage

- Sustainable Sites – Credit 7.1 – Heat Island Effect/Non-Roof

- Sustainable Sites – Credit 7.2 – Heat Island Effect/Roof

- Material and Resources – Credit 2 – Construction Waste Management

- Material and Resources – Credit 4 – Recycled Content

- Indoor Environmental Quality – Environmental Tobacco Smoke (ETS) Control Prerequisite

LEED buildings can help save energy, conserve resources, protect occupant health, and improve owners’ bottom lines. LEED-NC (new construction) is the most widely used standard and Poligon is here to help ensure your next project is a LEED-NC project. If you would like more information on Poligon’s LEED programs, please let us know here.

Warranty

Poligon’s warranty is one of the best in the industry. They stand behind their product long after the competition’s warranties have evaporated. Their current warranty includes:

- 10-year limited warranty on steel frame members.

- 10-year limited warranty on paint system.

- Pass through warranty of roofing manufacturer’s warranty.

If you have questions about the above warranty or require specific details regarding the above warranty, please let us know here.

Installation

Poligon designs structures that are easy to assemble and built to last. They are all pre-engineered, pre-manufactured, bolt-together systems with no site welding or cutting of steel framework required. Each shelter comes with sealed engineer drawings and installation instructions and can be assembled with normal expertise and with tools found in construction trades. The framing system of Poligon is such that it hides unsightly nuts and bolts and also eliminates access for bird nesting, which is a Poligon trademark. Poligon also offers an installation certification program for those construction companies who wish to become Poligon certified installers. If you would like more information on this program or you require a certified installer, please let us know here.

Considerations

While conceiving of the idea of what could be, consider the benefits to the neighborhood, community, local businesses, environment, and health benefit opportunities with a greenspace to share and enjoy. In supporting your local area by providing a vital space for all to utilize, you have directly and indirectly impacted so many lives and livelihoods. Greenspaces give us back our connection to nature and Poligon gives us the opportunity to create useable and sustainable outdoor environments to share and enjoy now and in generations to come. Let’s make something beautiful to last for the future.